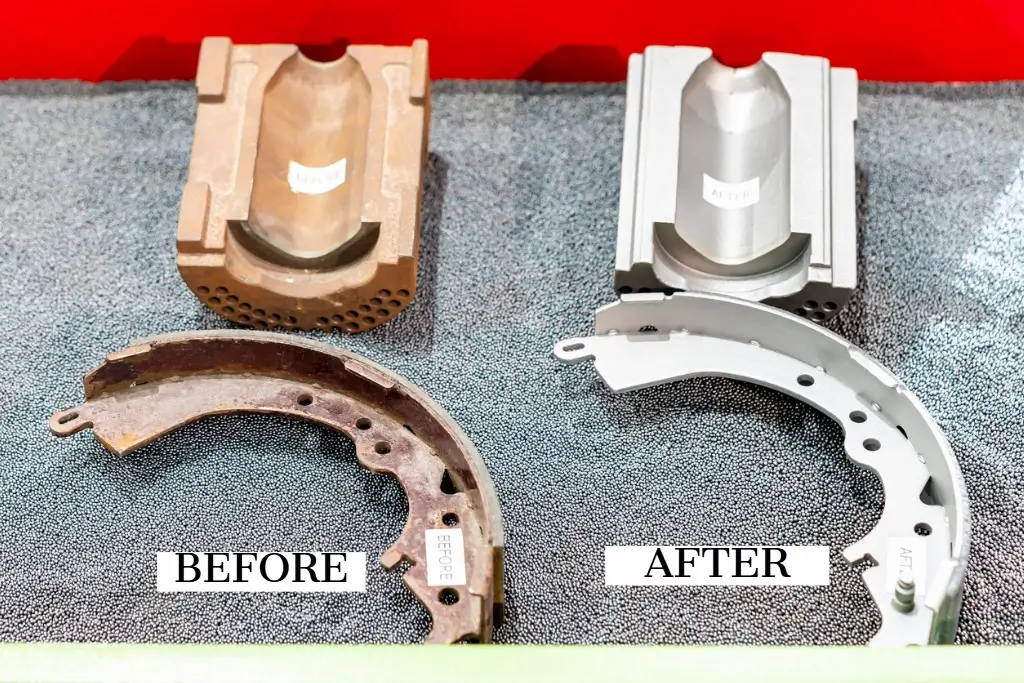

Abrasive Blasting

Abrasive sandblasting is a highly effective surface preparation method that removes rust, paint, grease, and contaminants, leaving a clean finish ideal for coatings. At Bright Steel Coating & Sandblasting, we offer expert sandblasting services tailored to industries like heavy engineering, construction, and manufacturing. Our skilled team handles projects of all sizes with precision, using eco-friendly materials and advanced techniques to ensure quality, safety, and durability. Trust us to deliver superior results that enhance coating adhesion and extend the lifespan of your assets.

Advantages of Abrasive Sandblasting

- Thorough Cleaning – Removes rust, paint, and contaminants efficiently.

- Versatile Applications – Suitable for various materials and industries.

- Eco-Friendly – Uses non-toxic, environmentally safe abrasives.

- Time-Efficient – Speeds up surface preparation compared to other methods.

- Cost-Effective – Reduces maintenance and repair costs long-term.

- Customizable – Adjustable techniques for heavy-duty or delicate work.

- Aesthetic Improvement – Restores and revitalizes surface appearance.

- Reaches Difficult Areas – Cleans intricate details and hidden spots.

- Safe and Reliable – Preserves material integrity when done by experts.

- Enhanced Coating Adhesion – Prepares surfaces for durable coatings. Removes rust, paint, and contaminants efficiently.